Hybrid Capacitors Panel

Advance Panels is one of the leader in manufacturing of most reliable “Hybrid Capacitors Panels” in India.

In last 40 years Advance Panels has manufactured & commissioned 5000+ MVAR Plus capacitors panels in various Data centers, Steel Plants, Glass Industries, Sugar, Papers, Plywood, Cement, Power, Hospitals etc. applications. we have offer technical solutions with products like Epcos ,Shreem , Schnieder, L&T etc. on pan India basis.

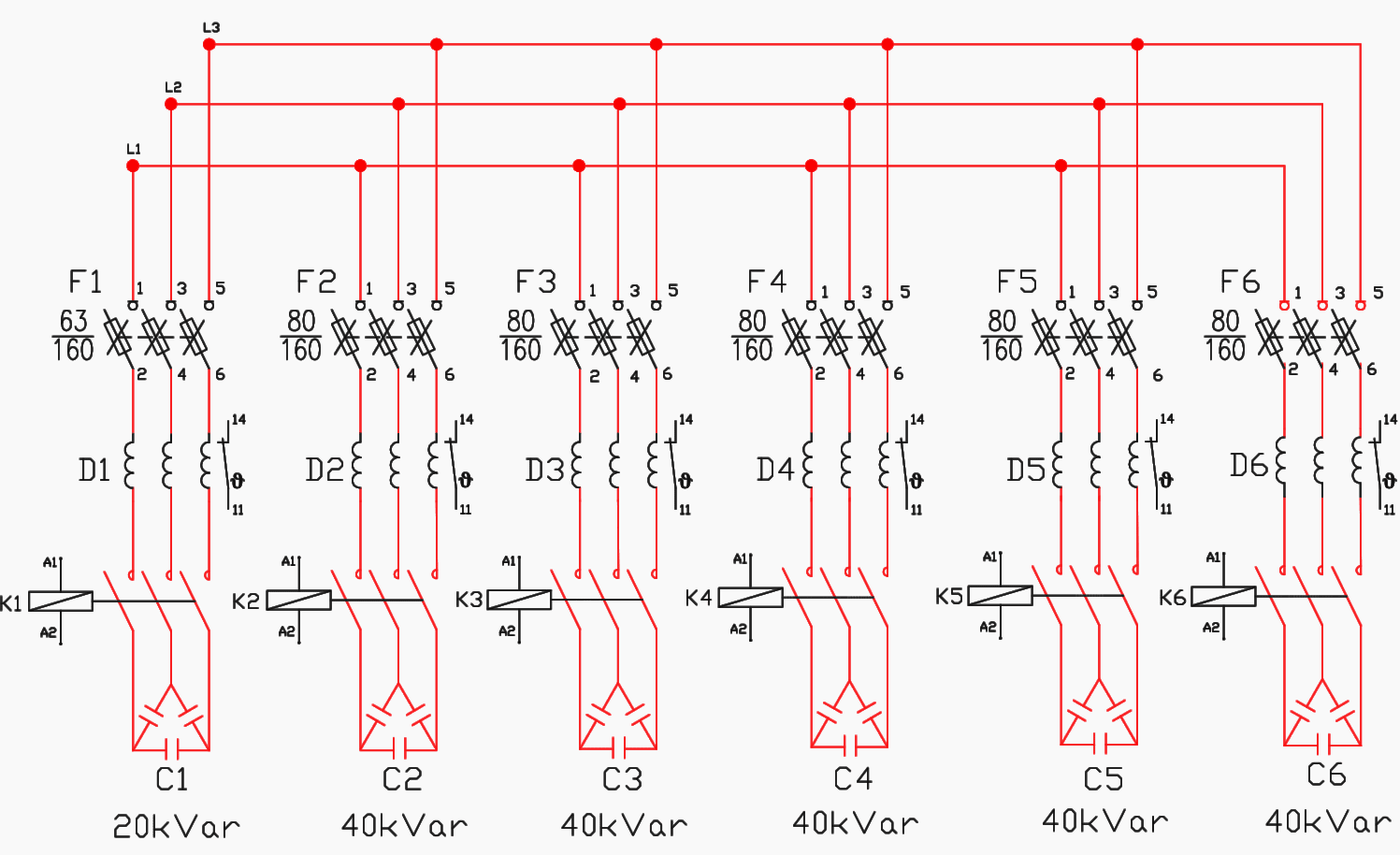

APFC Panels (Conventional Type)

We have been manufacturing and supplying “Conventional APFC Panels (Automatic Power Factor Improvement) with various capacities of Capacitors, Multi steps relays with protection devices.

Limitation of Common Capacitor Panel

- Steps Switching of Capacitors

- Power Factor can be improved up to O.92 max

- Displacement (Laggings) PF compensation only

- Ineffective with fluctuating loads

- High Maintenance and Capacitor replacement

- No Harmonic Compensation & No load balancing

- Substitute Technology is cost effective when only displacement (Laggings) PF improvement required.

Introduction of “Active Hybrid Capacitors Panels”

Advance make Hybrid APFC (AHPFC) is replacement of the traditional contactor based and thyristorized APFC with the advantages of active technology with step less reactive power compensation with accurate correction in Grid Supply and Generators. Correct selection ensures ultrafast compensation compliance with prescribed harmonic limits, maintaining unity power factor and reducing KVAH Energy charges and peak demand charges thus ensuring No Penalty and cost savings.

Unique Features of AHPFC Panels

- Modular / Bolted Constructions, Foldable Design, Both Side Expandable Type.

- Bus Bar Design available in Copper and Aluminium

- Reference Standards IEEE 519-1992 harmonic standard.

- Harmonic Filtering : 3rd to 25th Order with individual harmonic selection

- Compensation : close loop

- Rated current for Main Bus / ACB Feeder – 4000A

- Operational Voltage – 415 V, +10% - 15% VAC

- Rated Frequency – 50 Hz +/-5%

- Degree of Protection - IP 4X/ 41/42

- Rated short time withstand current – 50kA, 65kA at 415V

- Internal Segregation: Form Seperation 2B/3B

- Mechanical Impact – IK10

- Doors, Covers & Frames are very well gasketed with Neoprene / PU-Foam type gaskets

- Cubical is well ventilated with use of exhaust fan with louvers.

- Remote Monitoring: Ethernet based / Modbus RTU etc.

- Operator interface: Touch screen Display / Dedicated controller with operator activity log.

- Provision of Installation of Gas Flooding System.

- Hybrid PFC has an Active Power Filter coupled with heavy duty APP type detuned capacitor banks.

- Hybrid PFC offers benefits of Active Power Filter technology.

- A complete solutions in itself to take care of “Power Factor, Harmonics, Load Balancing & Neutral issues.

- Hybrid PFC can be programmed for

- Reactive Compensation

- Harmonic Mitigation

- Neutral Compensation ( 4P/4W)

- Load Unbalance

Benefits of “Hybrid PFC Solutions”

- Instantaneous true PF compensation up to unity

- Step less reactive compensation

- Reaction in micro seconds

- Lagging / Leading both compensation

- Runs on Generators as well grid

- Load balancing & neutral compensation (4P/4W System)

- Low Maintenance and longer life

- Harmonic compensation as per IEE- 519 Standard

- >1.5% improvement on losses, avoids jerk loading effect

|

Comparison Hy PFC Vs Conventional

|

|

Parameters

|

Hybrid PFC System

|

Existing

|

|

Performance

|

|

T ethnology

|

IGBT based with detuned AC capacitor

|

Capacitors

|

|

Speed

|

<0.2 milli second

|

> 50 milli second

|

|

Efficiency

|

>98%

|

93%

|

|

Current Injection

|

Stepless current compensation

|

stepped kVAR compensation

|

|

Effectivness

|

effective with high fluctation load

|

ineffective with fluctuating load

|

|

Leading/ Lagging PF

|

Both Leading & Lagging PF

|

Lagging PF compensation only

|

|

Load Balancing

|

Negative sequence current injection to balance grid current.

|

No load balancing

|

|

Harmonic mitigation

|

Harm o ni c co rn pen sati o n

|

No harmonic compensation

|

|

Neutral Compensation

|

possible with 4 wire system

|

Not possible

|

|

Maintenance

|

|

Maintenance Requirement

|

Modular design for easy maintenance

|

Easy Maintenance

|

|

Average Life

|

8 -10 years

|

2to3 Yrs (Recurring cost of capacitors)

|

|

Return on Investment

|

|

Overall system efficiency

|

High

|

Lew

|

|

Space

|

0.7 X

|

X

|

|

Capital cost investment

|

1.4 X

|

X

|

|

Lew operating cost

|

Reojrring cost of capacitors

|

|

Return On Investment

|

Improved PF

|

Ineffective with fluctuating loads

|

|

Better voltage profile

|

introduce voltage transients

|

|

Reduced faiure

|

Can increase failure due to harmonics

|

Typical Installation References

- 3 Nos. 1650 kVAR “Hybrid Capacitors “ Panels at AIIMS Bhatinda

- 4 Nos. 780 kVAR, 650kVAr, 650kVar, 780kVAr “Hybrid Capacitors” panels at M3M_ Gurgaon

- 6 Sets of 850 kVAr “Hybrid Capacitors“ panels at Bharat Electronics.

Get in touch